Laser machining

by Orion Laser Tech

Wide range of processes

Our laser technology offers distinct advantages over mechanical machining and other classic laser machining systems. By using ultra-short laser pulses we are able to realize high quality end products on an industrial scale.

Ablation

Cutting

Consecutive ultra-short laser pulses are fired in a specific pattern. With this process, a precise cutting edge with unprecedented edge quality is produced. All designs and shapes are possible, including internal contours. Think of dashboard consoles, windows and mirrors, …

Drilling

Laser pulses can completely remove the material locally. This can be used to drill glass with extremely low wall taper and little to no micro cracks. Beyond drilling of holes, any cut-out shape is also possible.

Chamfering

Laser machining generally eliminates chamfering because the end product already has smooth cutting edges. However, for cosmetic reasons or safety applications additional chamfering can be provided. Consider windows, mirrors or glass surfaces in the automotive industry.

Advantages

Dry process, no fluids used

Less material waste

Nesting on big plates

Complex geometries in 2D and 3D

Processing speeds of 1000 mm/s and higher

Lower operation costs

Pristine cosmetic quality

Every process is a tailored design

No need for post processing

No material damage, no cracks

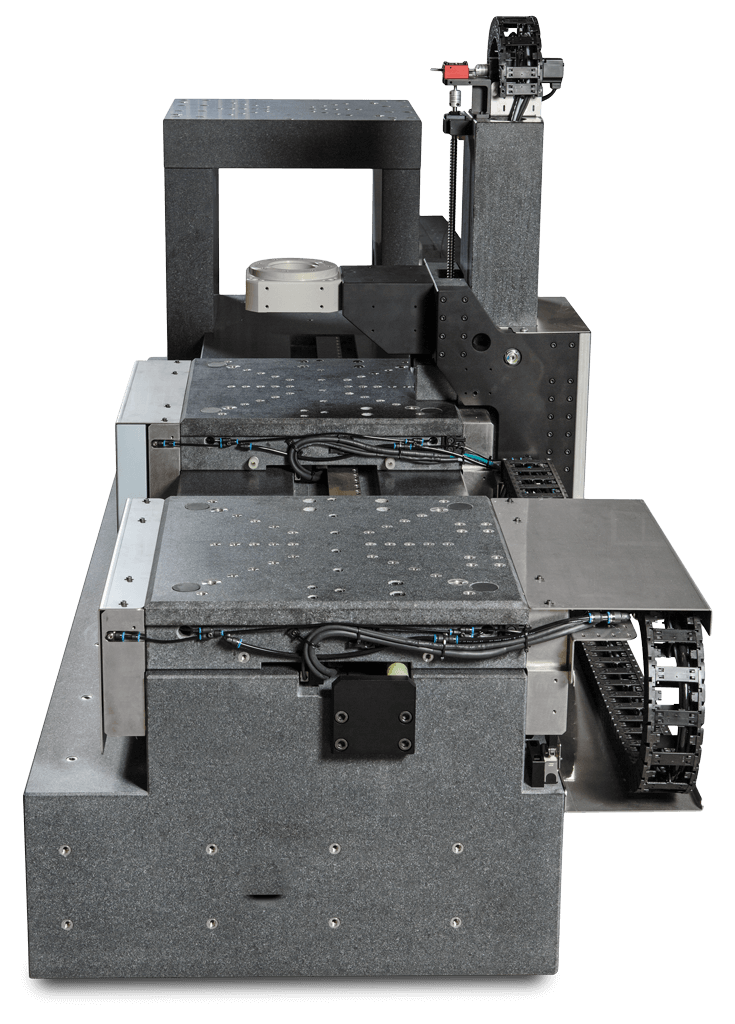

Micro positioning

High-precision motion technology

As a division of Leuven Air Bearings NV, the Orion team is backed by over 15 years of experience in development and production of high-precision air and ball bearing systems. We take great pride in our ultra-precision motion technology (up to nanometre accuracy). It allows us to ensure fast operation speeds under heavy load and to maintain the highest level of accuracy during laser processing. We offer cutting-edge bearing technology, high-performance direct drives, servo drivers, high-accuracy positioning feedback and integrated motion control. Looking for rotary, linear or multi-axis systems? Orion Laser Tech combines laser technology and precision motion technology into a turnkey laser application process.

Materials

We are experienced in different types of glass. Even extremely thin layers of glass (30 µm) are possible. Processing speeds can reach up to 1000 mm/s, while always maintaining superb quality. This ensures maximum output and yield in high volume production cycles, like display production.

Innovation

Trust our experienced team of engineers to realise custom innovations in your process. Our approach ensures we jointly come to a unique solution tailored to your needs. Working with Orion Laser Tech will offer you new insights on possibilities to make future innovations. Together we will innovate to transform your glass processing into a better version of itself and stay one step ahead of the market.